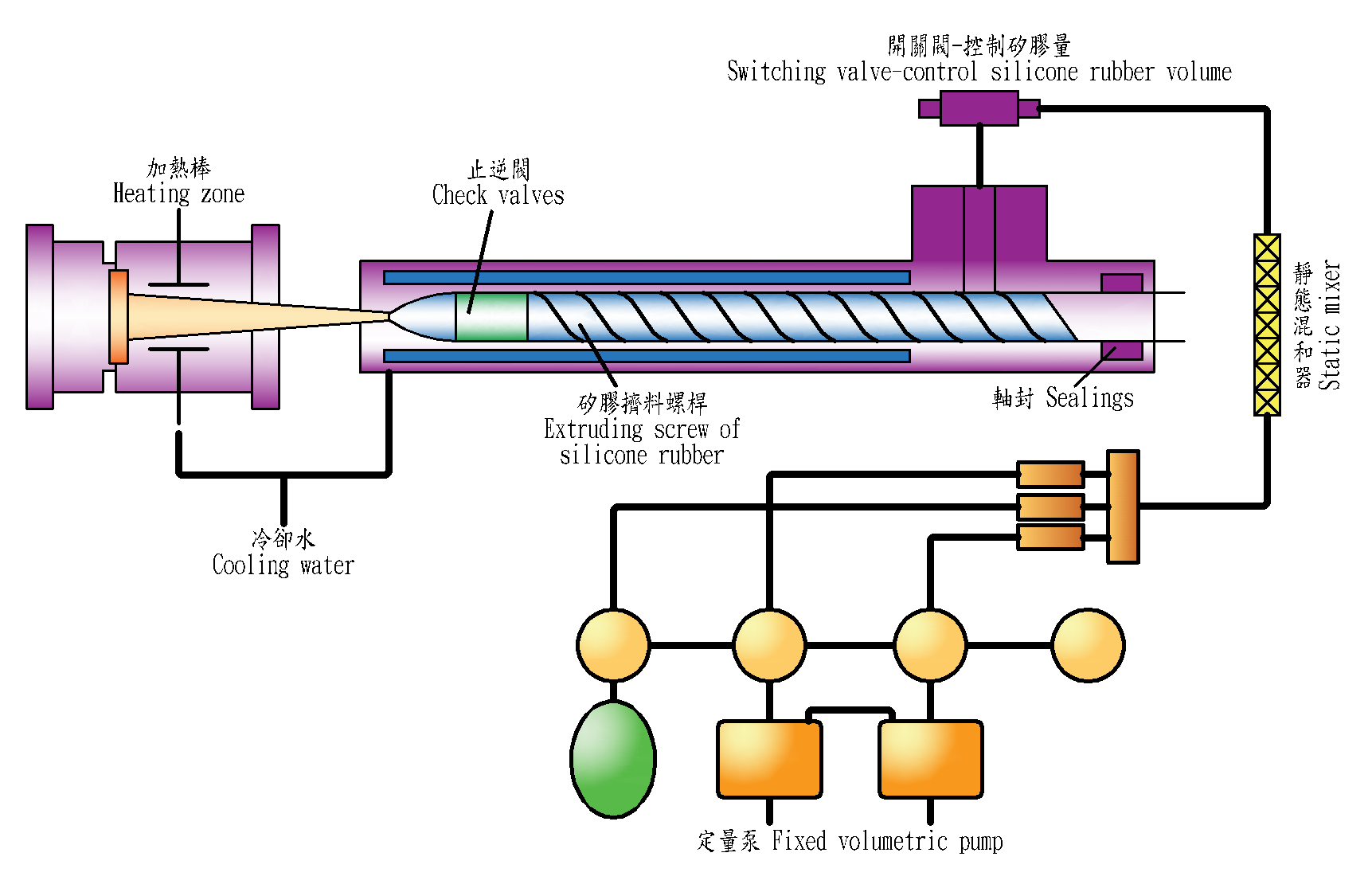

液態矽膠供料機 LSR Feeding System Equipment

本系統採用液態矽膠 LSR 為材料,分為A膠與B膠,利用定量裝置控制兩者為1:1之比例輸出LSR 原料,色料或添加劑在此階段添加,透過靜態混合器予以充分混合後將混合物泵送至加工機器,注入射出料管再進行射出成型生產矽膠LSR產品。若干產品如:潛水蛙鏡、奶嘴、氧氣罩要求透光性之產品,除以LSR材料製作外並無它途。

The ACQU-Silicone Rubber LSR injection moulding system is adopted the ACQU-Silicone Rubber as raw material and divided into A&B rubber and controlled 1:1 ratio by fixed volumetric device, the dyeing material & additives beaded at this stage and mixed completely due to the static mixed, thus the mixed material will be pumed to LSR injection moulding m/c and pass through injection cyl, and injection moulding product finished, such as: submersed swimming-wares, nipple, oxygen mask etc.. need visible-penetrated products, which solely from LSR material.

LSR液態矽膠射出示意圖 Liquid Silicone Injection LSR Schematic

|

液態矽膠供料機系統規格 Specifications for LSR Dosing Machine |

||

|

型式 Mold |

5 Gal (20Kg) LSR |

50 Gal (200Kg) LSR |

|

使用空氣壓力 Air pressure |

2.5~6.5 bar |

2.5~6.5 bar |

|

動力 Power |

2HP*4P∙30 50/60Hz |

2HP*4P∙30 50/60Hz |

|

最大工作壓力 Max. working vol. |

300 bar |

300 bar |

|

最大出料量 Max. unloading vol. |

400 cm3. /sec. (A+B) |

400 cm3. /sec. (A+B) |

|

設備尺寸 Unit size |

850*1050 mm |

1450*1200 mm |

|

最小高度 Min. height |

1500 mm |

2150 mm |